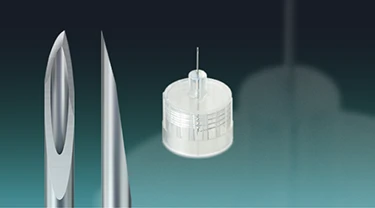

Technologies & SolutionsWorld's thinnest pen needle

Designed to relieve the pain of everyday injection.

Terumo’s ultra-thin pen needle shape that

redefines the conventional needle shape.

Terumo would particularly like to make daily injections less painful for children with diabetes. Injections are uncomfortable even for adults, and to minimize the risk of contact with pain receptors, the pen needle should be thinner. In order to reduce the insulin injection force which usually increases as the diameter of the needle becomes smaller, a slim double-tapered shape was adopted. Using its advanced technology, Terumo has achieved the world’s top-class thin pen needle design.

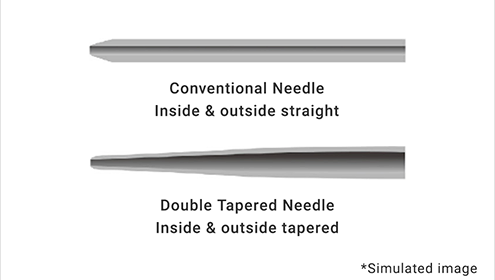

Slim double-tapered shape

Both the inside and outside diameters become thinner toward the end so that the force applied to the needle is dispersed.

To alleviate any insertion stinging or bleeding discomfort, and to reduce the insulin injection force which usually increases as the diameter of the needle becomes smaller, a slim double-tapered shape was adopted.

POINT01

Double-tapered shape — inside and outside

A double-tapered shape in which both the outside and inside diameters become thinner toward the end is employed.

Although the needle tip is 34G, it provides lower flow resistance than a conventional 32G pen needle.

POINT02

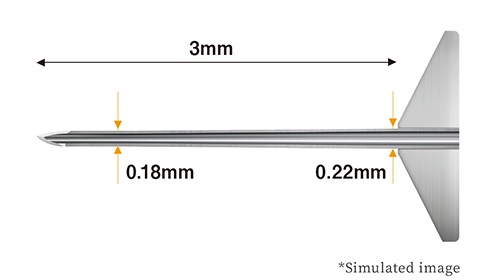

The needle thins towards the base of the needle, but ensures enough strength

The design incorporates a tapered shape that thins towards the tip. To alleviate pain, the needle’s base has been improved to a more slender and streamlined form. In addition to this, by moderating the taper angle, the force exerted on the needle is dispersed, thereby ensuring the requisite strength.

Double-tapered shape achieved with Terumo’s advanced technology that

requires micron and submicron accuracy.

Minimizing risk of contact with pain receptors,

Terumo makes the diabetes self-treatment environment easier, to reduce the burden on people with diabetes.

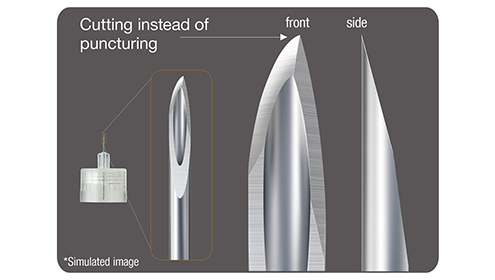

Asymmetric bevel

Terumo’s engineers arrived at this asymmetric bevel by trying out various configurations of bevel. This shape requires the strictest accuracy during manufacturing, making it difficult to mass produce while ensuring precision. Terumo was able to manufacture this needle with fine precision in large quantities, while maintaining its high quality by applying advanced production technology and stringent quality control.

POINT

Cuts instead of puncturing

Terumo has developed an asymmetric bevel that cuts the skin instead of puncturing it. This effectively decreases penetration resistance.

Combine Terumo’s advanced technologies with your business –

as subcutaneous administration for self-injection increases in popularity.

Terumo provides less painful self-treatments.

Our Care

Hisao Nishikawa

Involved in the development of blood glucose measurement since 1997. Transferred to the development team of ‘Nanopass 33’ in 2001 and has worked across the entire process from concept planning to the launch of mass production. He has also been leading the further development of the Nanopass series since then.