Our CareWorld's thinnest pen needle

The driving force behind the development of the ‘less painful injection needle’ was the desire of our engineers to help children with diabetes, after learning what they are going through.

If we can reduce the pain of injections,

we could provide more quality time for people with diabetes.

No one likes needles, not even adults, let alone children, because injections can be frightening and painful.

People with type 1 diabetes must have insulin injections every day.

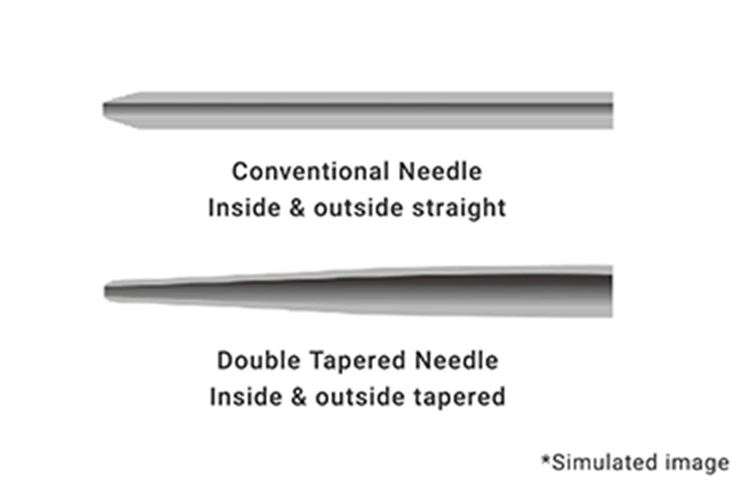

Terumo therefore set out to develop the ‘world's least painful’ injection needle. And based on that ambition, the ‘Nanopass series’ disposable needles for pen injectors were created. ‘Nanopass 34G,’ the world's thinnest double-tapered pen needle* with an outer diameter of only 0.18mm at the tip was released in 2012, and ‘Nanopass Jr.’ with the needle length shortened by 1mm, from 4mm to 3mm, was introduced in 2019.

Hisao Nishikawa, one of the engineers of Nanopass, has been working on this product for more than 20 years. His first involvement in the development was with ‘Nanopass 33,’ which was launched in 2005. As he had originally been working on the development of a blood glucose measurement device, he already had a certain amount of knowledge about diabetes and people with diabetes, but during the development of the injection needle, he was able to learn the opinions of children with diabetes and their parents through a needs assessment.

Nishikawa: “Insulin injection is an indispensable treatment for people with diabetes. And I came to the realization that we have to hear not only from children with diabetes, but also from their parents. For in many cases, if the child is too young to inject him/herself, the parents have to handle it, and feel a sense of guilt at having to stick a needle into their child. I wanted to help alleviate that distressful feeling as much I could and that was my motivation for developing this product."

The desire to ‘to do something’ for them became the driving force to realize the world’s ‘least painful’ and thinnest pen needle*.

-

*

Based on research by Terumo Corporation in .

‘Double-tapered shape’ that’s injectable with reduced force.

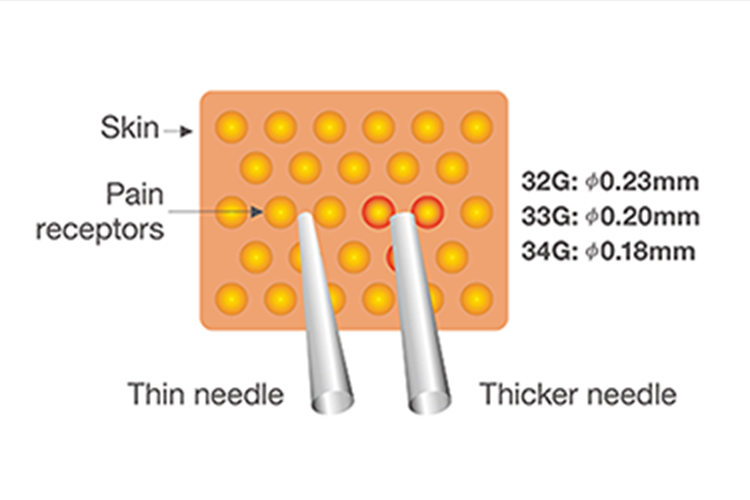

There are two reasons why the Nanopass needle can be inserted with less pain. The first is the small diameter of the needle and the second is the asymmetrical shape of the needle tip.

Nishikawa: “Pain is felt because the insertion point of the needle touches pain receptors. On the dorsum of the hand, there are 100 to 200 pain receptors per cm2. So, the reasoning is that if the diameter of the needle is smaller than the distance between the pain receptors, it is less likely to hit the pain receptors and cause pain."

But, mass production of this shape was extremely difficult. It did not yet exist anywhere in the world, and Terumo did not have the know-how to realize it within the company. So, the team searched for outside partner companies, contacting more than 100 corporations, but could not get a favorable response due to the technical hurdles. The team was on the brink of losing hope. At that time, not a few people in the company thought it would be difficult to successfully turn the idea into actual production, while admitting the idea itself was good.

However, Nishikawa and the rest of the development team kept their spirits up by remembering their original mission for the development, which was to ‘reduce the burden on people with diabetes.’ Finally, they found a partner who could take on this difficult challenge together with Terumo. It was a small factory in Japan, known for its hardcore craftsmanship. The mastery of their skills and strong spirit helped Terumo succeed with mass production of the double-tapered shape needle tubes. This was the moment when the development of Nanopass took a great step forward.

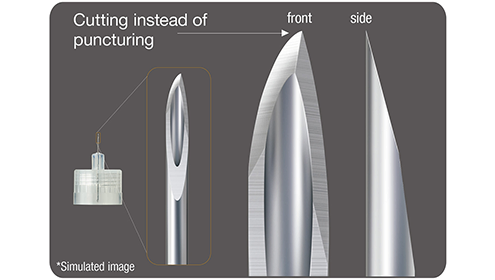

‘Asymmetric bevel’ that reduces pinprick pain.

There is another innovation in Nanopass. The asymmetric bevel. The idea was to alleviate pain by applying this to the tip of the double-tapered tube.

Madoka Horie, who had joined the development team from ‘Nanopass 34,’ explains the asymmetric bevel as follows.

Horie: “That pinprick sensation you feel during an injection is produced when a sharp object hits the skin. On the other hand, when a knife blade is pressed against the skin, it does not hurt because the pressure is distributed linearly. The asymmetric bevel is designed based on this concept. There is a slight ‘line’ at the tip of the needle. The needle does not puncture the skin, but rather creates a tiny cut with its razor-sharp edge. This design has been adopted for the Nanopass series ever since.”

There was serendipity involved in the discovery of the asymmetric bevel.

Nishikawa: “We were making and testing various prototypes to discover which shape would alleviate pain the most, and one day I came across a needle that actually didn’t produce a pinprick pain. When we magnified it under the microscope, we found that the left and right sides were asymmetrical. Until then, it was a common-sense assumption that a needle must be symmetrical, so at the time we were trying to achieve this. As we made samples by hand in the early stages of development, a defective shape happened to be produced in error, and as a result this led to the serendipitous discovery of the innovative feature, the ‘asymmetric bevel’.

An idea born from a desire was transformed into reality by calling upon the wisdom of Japanese manufacturers.

Mass production of the needle tubes was finally on track. The shape of the tip was also decided. However, there was one more major obstacle. It was the Monozukuri or manufacturing technique of converting them into actual injection needles. Terumo's Kofu plant manufactures hundreds of millions of needles every month, but it had never made such ultra-thin needles before.

There were a large number of manufacturing issues to be addressed, such as high-speed, micro-welding of ultra-thin tubes, correction of heat-induced deformation, and efficient attachment of the needles to the needle base.

Hideo Kawamoto, who has been involved in the development of the Nanopass 33 since its release in 2005 like Nishikawa, looks back on that time as follows:

Kawamoto: “Since the Nanopass 33 was too thin, the tapered needle would bend or break. Each time that happened, we redesigned and reconstructed the shape. We performed simulations of the tip many times.”

But Nishikawa and other engineers succeeded in mass production by solving such problems one after another. They realized the technology necessary for the mass production of Nanopass with the cooperation of equipment manufacturers of various different industries, such as automotive and precision instruments. The strong desire to bring this solution to reality for the sake of people with diabetes led to a gathering of technological capabilities that at times transcended industries.

Furthermore, a full inspection is conducted on Nanopass series products by imaging inspection machines after the final assembly process. The defect rate is close to zero, achieving efficient mass production of the products while maintaining the highest Japan quality.

From ‘pain-relieving’ needles to ‘less scary’ needles.

After developing ‘Nanopass 34G’ with a tip outer diameter of 0.18mm in 2012, Nishikawa and his team next set out to develop a needle that is ‘less scary.’

The question was how they could alleviate the fear of injections. The answer was to reduce the length of the needle from 4mm to 3mm.

Kawamoto says that hearing people with diabetes’ requests for “something that causes as little pain and fear as possible” made a slight change in his motivation for the development.

Kawamoto: “We only shortened it by 1mm, but if that needle can alleviate the pain and fear of small children and others, then I felt strongly that we had to aim for an even thinner needle that would respond to people with diabetes’ requests.”

Horie: “Appearance seems to have a big impact on feeling. Having been involved with Nanopass since the development of the 34 gauge, I wondered how much of a difference it would make to go one gauge thinner as the difference is only 0.02mm. But when you actually see it, the impression it gives is completely different, and there was an enormous positive response from both doctors and people with diabetes."

In order to reduce the suffering of people with diabetes as much as possible, the passion of the engineers involved both internal and external partners and led to the realization of a thin, short needle that reduces pain and fear.

With our technologies and quality products,

we would like to stand alongside people with diabetes around the world.

Through the development of Nanopass, the feelings of engineers toward people with diabetes have become even stronger.

Nishikawa: “My experiences in developing diabetes products gave me a chance to think of patients and professionals more closely. The more I got to know about them, the more I wanted to develop products that are more helpful and efficient for them to use.”

Horie: “Diabetes-related products are unique in terms of medical devices used by various people, including those with diabetes themselves. We want to make products that are not only functional and efficient, but also comfortable to carry around on a daily basis.”

Kawamoto: “Self-injection is a part of people with diabetes’ lives. Recently, I’ve been looking more often at people with diabetes’ posts about their daily lives on social media to learn more. Some of the comments are positive about Terumo, and some are expressing further expectations. But I believe it is these comments that hold the hints for the next products we should aim for.”

Together with their partners, Nishikawa and other engineers hope to make the lives of people with diabetes less stressful, not only in Japan, but also worldwide.

Kawamoto: “I’d like to keep contributing to reduce the fear and resistance to injections through Nanopass. I also hope that one day this needle will be used not only for people with diabetes, but also in other medical fields.”

Horie: "Terumo places great importance on the quality of its products, and Nanopass provides good quality with a very low defect rate during production. I think it will also be a great opportunity for further enhancing the brand value of our potential partners.”

Nishikawa: “While continuing to increase the popularity of Nanopass worldwide, I would like to work together with pharmaceutical companies and medical device manufacturers to provide quality products and services throughout the world so that many people with diabetes are able to live their lives with less pain and fewer difficulties.”

The injection needle is an essential device for accessing the human body, and the technologies used for Nanopass can be utilized for a variety of products, such as drug injections. Nishikawa and his team members will accelerate their efforts with the aim of crystallizing their ideas into new innovations through further refinement and improvement.

Profile

Hisao Nishikawa

Involved in the development of blood glucose measurement since 1997. Transferred to the development team of ‘Nanopass 33’ in 2001 and has worked across the entire process from concept planning to the launch of mass production. He has also been leading the further development of the Nanopass series since then.

Madoka Horie

Joined Terumo in 2007.

After developing test strips for measuring blood glucose and urine composition, she joined the development team of ‘Nanopass 34.’ As a student, she studied methods of searching for marker molecules which could be used in the treatment of diabetic nephropathy.

Hideo Kawamoto

Joined Terumo in 2005.

Involved in product improvement and production technology as a member of the Nanopass 33 development team, he utilized the experience gained to lead Nanopass 34 from commercialization of improved concepts to the start of mass production.

Technologies & Solutions

Double-tapered shape / asymmetric bevel

To minimize contact with pain receptors, Terumo realized the world's thinnest double-tapered 34G pen needle*

-

*

Based on research by Terumo Corporation in .